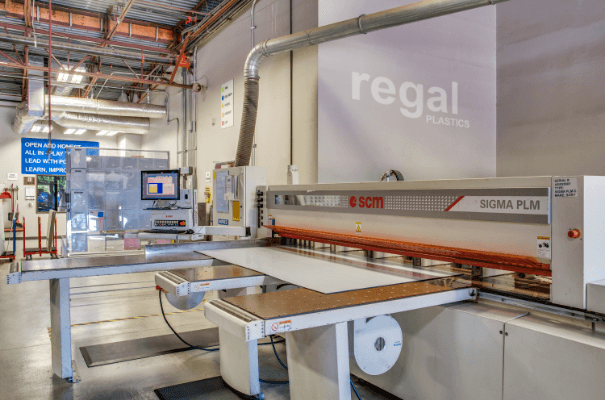

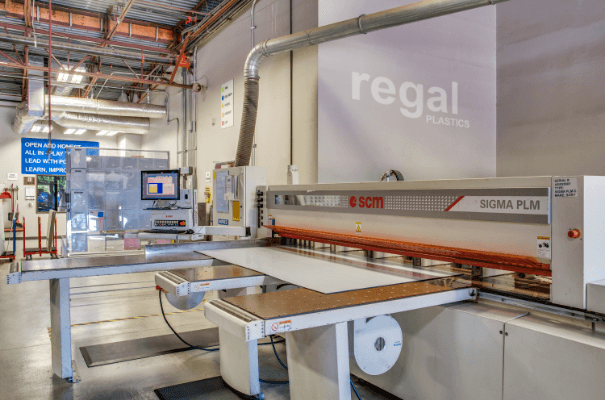

Saw Cutting

Need a sheet cut-to-size? We can cut any material in our warehouse with fast turnaround times as in, same day, if needed. Our team uses a cut calculator to ensure we get you the perfect yield with the lowest amount of sheets utilized. We guarantee tight tolerances whether you need one or 1,000 pieces.

Material: Any standard 4’x8’ sheet or custom sized sheet in our warehouse

Acrylic Fabrication & Bonding

We specialize in custom acrylic fabrication including design, assembly, bonding, and edgework. Every custom fabrication customer has an account manager that remains their point of contact from initial design through completion, so customers can call or text anytime to get a status update. Our skilled in-house fabrication team offers years of experience, so our customers get fast turn around times on high quantity orders or museum quality joints on display pieces.

Material: Acrylic .060” - 4”

Applications: Here are a few of our most common projects, but if you need clear acrylic fabricated, we can help.

Boxes - Displays - Vitrines - Furniture - Nema enclosures -Information boards - Bonnets

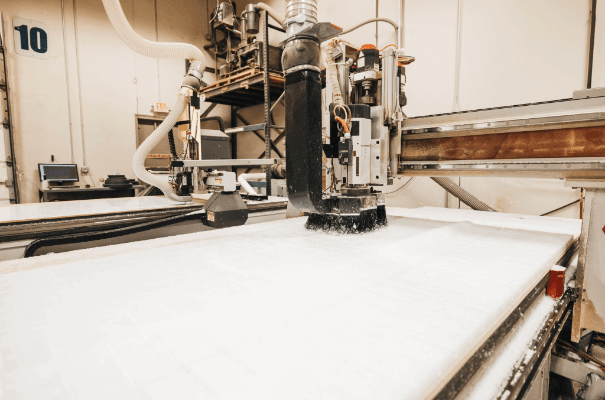

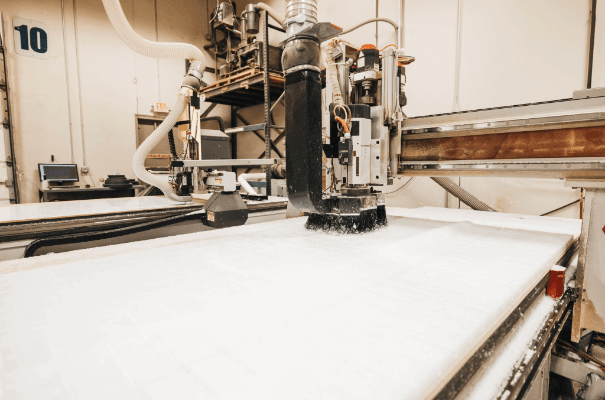

CNC Routing

Each of our locations has CNC machines and material in stock, so we can have your project ready for pick-up or out for delivery fast. Already have a file? We can route it. Need a file? Our CNC specialists can draw it. Our customers work one-on-one with a project manager, and all work is completed in-house to ensure quality and tight tolerances. You can call, text, or email at any time to check on your project’s status.

Material: Acrylic, Polycarbonate, ABS, Polyethylene (PE), Polypropylene

Plastic Welding

All of our plastic welding customers get an account manager that works with them from initial consultation to completion. Each tank is built to order, so customers can submit custom designs with no minimums required. The welding is completed in-house, so customers can call or text to check on progress. Plastic has become a popular choice for fluid handling applications due to its longevity, chemical resistance, and moisture resistance. It is non-conductive and offers FDA approved options.

Material: Polyethylene, Polypropylene

Applications: Here are a few popular applications, but we can custom weld your unique needs.

Pickling tanks - Galvanizing tanks - Trays - Sink - Waste tanks - Large shadow boards - Lean workcarts and stations

Plastic Edgework

Whether you are looking for professional flame polishing for your acrylic or rounded corners for your cut sheets, our fabrication department can add the final touch to your project. We offer a wide range of options and levels of finish. Ask about our:

- Specialty bevels

- Machine and flame polishing

- Buffed Edges

- Rounded corners

High-End Acrylic Bending

We offer high-end acrylic bending, specializing in material ¼” or thicker. Your account manager will work with your individual needs and keep you updated as we build the mold and finish your project. Each mold is custom built to ensure a visually appealing bend and accurate end dimensions.

How To Order

Submit a RFQ

You can submit an RFQ with or without a drawing. If available include material, application, and when you need it completed by in the message box.

Receive/Review Quote

A sales representative will contact you with a quote and an estimated lead time. If you dot not have a drawing our fabrication specialist will draw out your project and email you for approval.

Timeframe & Deposit

Upon your approval of the quote, your sales representative will contact you with a completion date and required down payment.

Project Production

After we receive the agreed upon down payment and your approval of the completion date, we will get the project into production.

We Call You When It’s Done!

Have additional questions about our quote process? Click here to review frequently asked questions.

Here’s Where To Order!

Custom Fabrication Quote Quote Your ProjectWe specialize in plastic solutions customized to your company's needs. We can fabricate your custom project FAST to spec with tight tolerances. Contact us today to get a free quote.