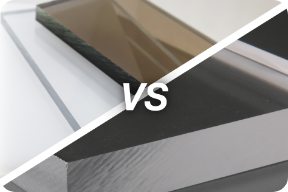

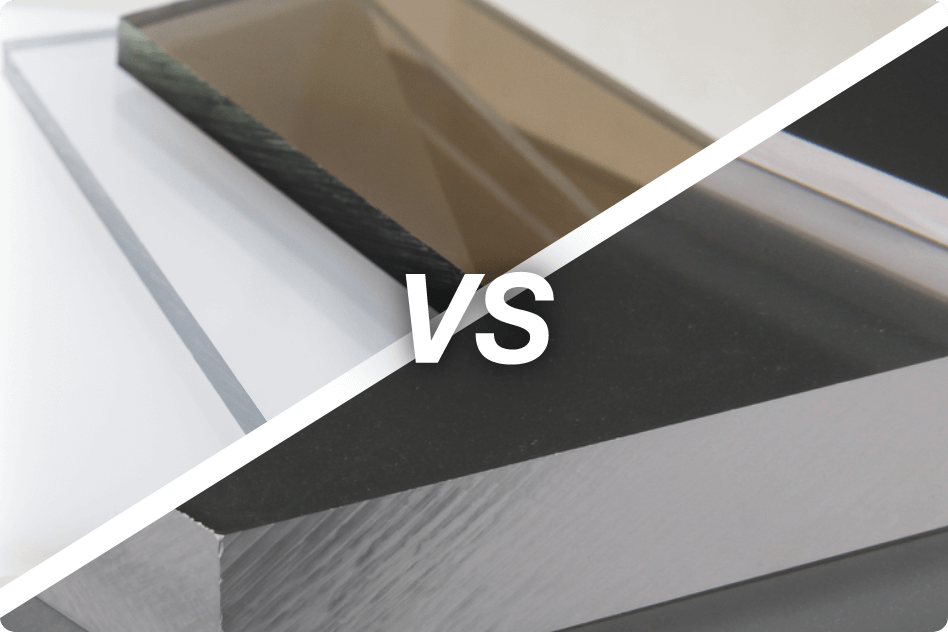

So, you're starting a new project and need to find the best material. You may be wondering about Lexan vs. plexiglass. Both have earned a strong reputation, often leaving designers scratching their heads over which one to use.

Lexan, a champion in toughness, is frequently spotted in everything from eyewear lenses to protective shields. On the other hand, plexiglass, known for its crystal-clear clarity, often takes the stage in art galleries and aquariums.

The decision of plexiglass vs. Lexan can seem daunting, but understanding their unique qualities and applications can help you identify the perfect fit for your project. By the end of this article, you'll have a clearer view of which material best suits your needs.

Table of Contents:

Plexiglass vs. Lexan: History and Development

When it comes to understanding materials, sometimes it helps to know where they came from. Let's take a step back in time and explore the origins of plexiglass vs. Lexan.

Plexiglass

In the 1930s, plexiglass was introduced to the market by companies like Rohm and Haas. Originally intended as a lightweight and shatterproof alternative to glass, it became a hit, especially during World War II. Aircraft windows, canopies and even submarine periscopes started using plexiglass because of its clarity and lightweight properties. After the war, its popularity didn't wane. Instead, it found a new audience among artists, architects, and homeowners.

Plexiglass is another name for acrylic, so if you've ever heard people wondering about acrylic vs. Lexan or Lexan vs acrylic, it's the same thing. Read our blog on the difference between plexiglass and acrylic to learn more.

Lexan

In the 1950s, scientists at General Electric were looking for new and robust materials. What they stumbled upon was Lexan, a type of polycarbonate. The discovery was a game changer. Suddenly, there was a clear plastic that was not just transparent but also super tough. It was quickly adopted in a variety of applications, ranging from eyewear lenses to CDs and DVDs.

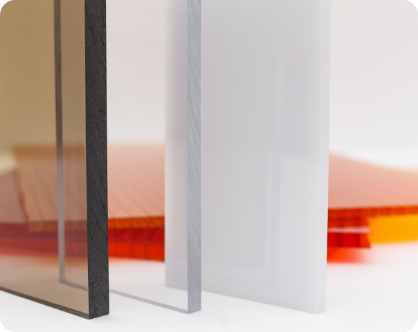

Lexan vs. Plexiglass: Composition and Manufacturing Process

When picking a material for a project, it's essential to know what it's made of and how it's manufactured. Let's break down the basics of Lexan vs. plexiglass to get a clearer idea of their makeup and production.

Lexan

Lexan is a polycarbonate composed of long chains of molecules linked tightly together, making it super strong. This strength is why Lexan can withstand high impacts without breaking. To produce Lexan sheets, the polycarbonate resin, which starts as small pellets, is melted and then cooled in flat molds.

Plexiglass

Plexiglass, on the other hand, goes by the scientific name polymethyl methacrylate (PMMA). Like Lexan, its strength comes from its molecular structure. But unlike Lexan, plexiglass is recognized for its high clarity, making it almost as transparent as pure water. When making plexiglass sheets, the PMMA resin is also melted down, but the process can vary. Sometimes, it's poured between two glass plates and then cooled, or it might be extruded through a mold to form sheets.

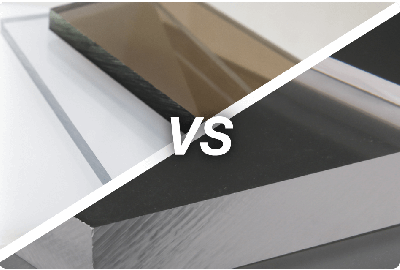

Lexan vs. Plexiglass: Key Characteristics

When it comes to Lexan vs. plexiglass, each has standout features that set them apart. Let's get to the heart of what makes these materials different.

Transparency

If you've ever looked through a window and thought it was super clear, there's a good chance you were looking through plexiglass. Known for its pristine clarity, plexiglass is a top pick for jobs where transparency is a must. Lexan is clear, too, but when compared side-by-side, plexiglass takes the crown for sheer transparency.

Durability and Strength

Ever seen those protective shields in banks or at some retail counters? That's Lexan in action. Its claim to fame is its super toughness. Drop it, hit it or try to bend it — Lexan stands strong. While plexiglass is also durable, when it comes to handling serious impact, Lexan is the go-to.

Weight

If you're considering a project where weight is a concern, you'll be happy to know both materials are lighter than traditional glass. Between the two, plexiglass is generally more lightweight than Lexan, making it easier to handle.

Plexiglass vs. Lexan: Advantages and Disadvantages

Knowing the pros and cons can make all the difference when deciding on materials. Let's weigh the advantages and disadvantages of plexiglass vs. Lexan to provide a clearer picture.

Plexiglass

Plexiglass's advantages are its:

- Superior clarity — For picture-perfect transparency, plexiglass stands out. It's a top choice for framing or any project where a clear view matters.

- Clear Edges and Glue Joints — Acrylic Plexiglass is the top choice for displays and museum vitrines. The material has transparent glue joints, and its polished edges have the highest clarity of any material.

Its disadvantages include the fact that it's more brittle than Lexan. While plexiglass is durable, it doesn't quite match Lexan's toughness. Under certain conditions, it might crack or break.

Lexan

Among Lexan's advantages are its:

- High impact resistance — If toughness is what you're after, Lexan is hard to beat. It can handle a lot without giving in, making it ideal for protective barriers or places with a lot of wear and tear.

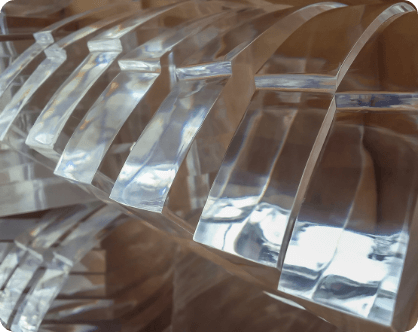

- Moldability — Need a specific shape or design? Lexan can be bent without heating or cold formed.

Lexan's primary disadvantage is that it's prone to scratching. Lexan is tough, but it isn't immune to scratches. Over time, without proper care, it might start showing wear.

Lexan vs. Plexiglass: Applications

Knowing the strengths and weaknesses of Lexan vs. plexiglass is just the start. Let's look at where you might commonly find these materials in action.

Lexan

You can find Lexan polycarbonate sheets in:

- Bullet Resistant windows — Lexan is often used where security is a priority. Its high impact resistance means it can take a hit and keep on protecting.

- Electronic displays — Have you ever wondered what keeps your smartphone screen or other device displays safe? Lexan offers a tough protective layer that doesn't compromise on clarity.

- Automotive components — Cars need materials that can handle a lot — from wind and rain to bumps and scrapes. Lexan is used in various parts, from headlights to sunroofs, because of its durability and flexibility.

Plexiglass

Plexiglass is a popular choice for:

- Aquariums — Fish enthusiasts trust plexiglass to keep their aquatic friends safe. Its transparency ensures a clear view, and its strength means it can handle the pressure.

- Picture frames — Want to frame a cherished memory? Plexiglass is a popular choice because of its clarity. It ensures photos and art are displayed at their best.

- Architectural details — Architects and designers prize plexiglass for its versatility. Besides clear plexiglass, they can choose from colored plexiglass and decorative plexiglass to create exciting details and furniture.

- Museum Quality Displays – Plexiglass has clarity second to none, and it is available with UV protective and anti-glare coatings.

Lexan vs. Plexiglass: Which Is Better?

When it comes to Lexan vs. plexiglass, the best choice depends on your requirements. Lexan is the top choice if your application demands strength. If transparency is your main concern, you'll want to go with plexiglass.

FAQs: Lexan vs. Plexiglass

As a leading plastics distributor, Regal Plastics is ideally suited to answer your questions concerning Lexan vs. plexiglass. Read the following for more information, and be sure to contact us for additional details.

What Is the Market Size for Lexan?

What Is the Market Size for Plexiglass?

What is the Strength of Lexan Compared to Plexiglass?

Lexan vs. Plexiglass: Find What You Need at Regal Plastics

Whether you require Lexan's superior durability or plexiglass's outstanding transparency, we have what you're looking for. The question of Lexan vs. plexiglass isn't an issue at Regal Plastics. We carry a wide range of both materials to meet our customers' specific needs. Browse our extensive inventory now and find exactly what you want for your next project.

REQUEST A QUOTE